Simplifying manufacturing processes and maintaining quality have helped bring the LED market to where it is, but a recent award from the National Science Foundation could really push direct-view LED displays into a viable direction.

Electrical distributors should soon see substantial savings thanks to an improvement in the time it takes to arrange the LEDs within the displays.

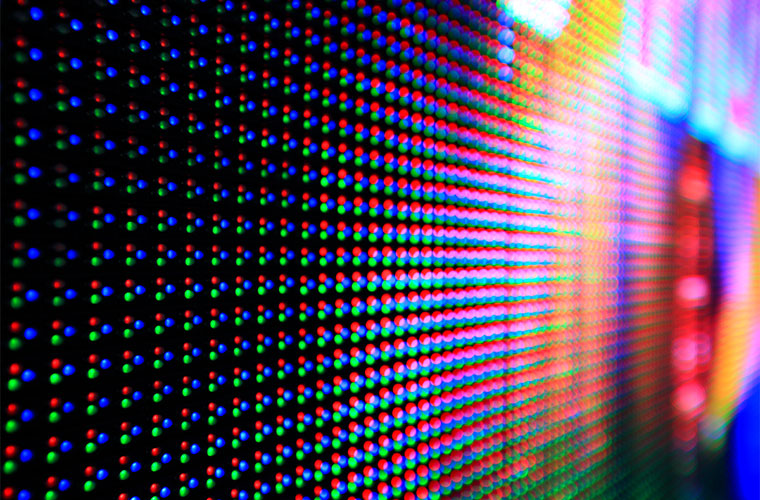

Currently, millions of LEDs have to be placed by robots to make a 4K display, unlike LCD displays (composed of a layer of liquid crystal sandwiched between two pieces of polarized glass). With a robot, the painstaking process can take weeks, if not months, depending on the size of the display. LED technology developer SelfArray Inc. has recently received an NSF grant that will help advance the company’s process, which uses a magnetic template and vibration and levitation to place the LEDs.

“Our goal is to create a process that facilitates the manufacture of a lower cost direct-view LED display that will replace current methods and displace LCD or OLED technology,” said Dr. Clinton Ballinger, CEO and Founder of SelfArray. He went on to suggest that there would be real benefits to reducing the time to construction by a factor of hundreds.

The advancement of the manufacturing process will likely increase the viability of electrical distributors offering direct-view displays, which are increasingly used in a variety of applications, such as airports and malls, for videos and non-point-light luminaires.

In fact, at least one lighting industry veteran says that the development has been coming for two years. “I have been talking for about two years about using magnetic templates to distribute LEDs for nanotechnology that uses LEDs that are the size of blood cells being printed using a print cartridge,” said Mark Lien, Illuminating Engineering Society industry relations manager. “The issue was random distribution. And a magnetic template would provide the necessary uniformity. This sounds similar for displays.”

If SelfArray can continue to develop on the early successes, direct-view LED would become a principal competitor to OLED technology, which only represents a fraction of the overall solid-state lighting market. That makes it a much more palatable option because of the ability to use loose LEDs in a massively parallel process for a variety of display sizes.

Human-centric lighting has become a focus for manufacturers and researchers alike, especially as it relates to productivity and health. The most common usage is increased blue light for productivity and decreased blue light for improved transitions towards sleep. In agricultural applications, reds (and now purples) play a critical role in improving plant growth.

“The use of OLED and the technology that SelfArray is developing when directed directly to the eye may provide effective circadian stimulus as described by the Lighting Research Center at Rensselaer Polytechnic Institute,” argues George Bosson, principal consultant at be*light. “This may contribute quite nicely to a circadian-balanced illumination solution.”

Coincidentally, RPI and SelfArray are both based in Troy, New York. So research into both elements, both the direct-view and related studies will likely come from the same small city in the coming years and hopefully expand solid-state lighting options for distributors who are often forced to compete on cost.

Tagged with direct displays, LED, lightED, manufacturing